Pikes Peak Build: Part 1

New year - new lots of Things

Back in March, we announced our plans to tackle one of the most difficult motorsport events in the world; the 102nd running of the Pikes Peak International Hill Climb in 2024. In preparation for this grueling challenge; which will test us as a team, me as a driver, and the car we build over a distance of 12.42 miles and around 156 turns on the way to a summit elevation of 14,115 feet, we decided to spend the next year taking our time to thoughtfully plan for a successful race to the clouds. While my mental-state and physical conditioning are equally important, for purposes of Part 1 let’s just focus on what most people care about more…the car!

Let’s start with some context first. Getting a car to the top of Pikes Peak quickly requires horsepower. And a lot of it. Because an internal-combustion engine can see up to 40% power loss from the start-line to the summit as the air gets thinner (less oxygen density) the farther you climb. That’s why it’s not uncommon to see the front-runners at PPIHC bring over 1,000hp to the race. Phew!

Since this is going to be our first time running the event, I opted for a more reasonable power goal of only 600hp; knowing full well that I might end up with only 360hp by the time I reach the summit. With our S54 powered E46 M3, this meant going the route of forced induction. I spent some time discussing and debating the pros and cons of a supercharger vs. a turbocharger, and in the end I decided the thermal demands of running a turbo didn’t necessarily outweigh the gains for me. Keep in mind, a car also needs way more cooling to run up Pikes Peak than it does on a road course at sea level because of the thinner air, and the fact that you are on-throttle almost the entire time on the way up.

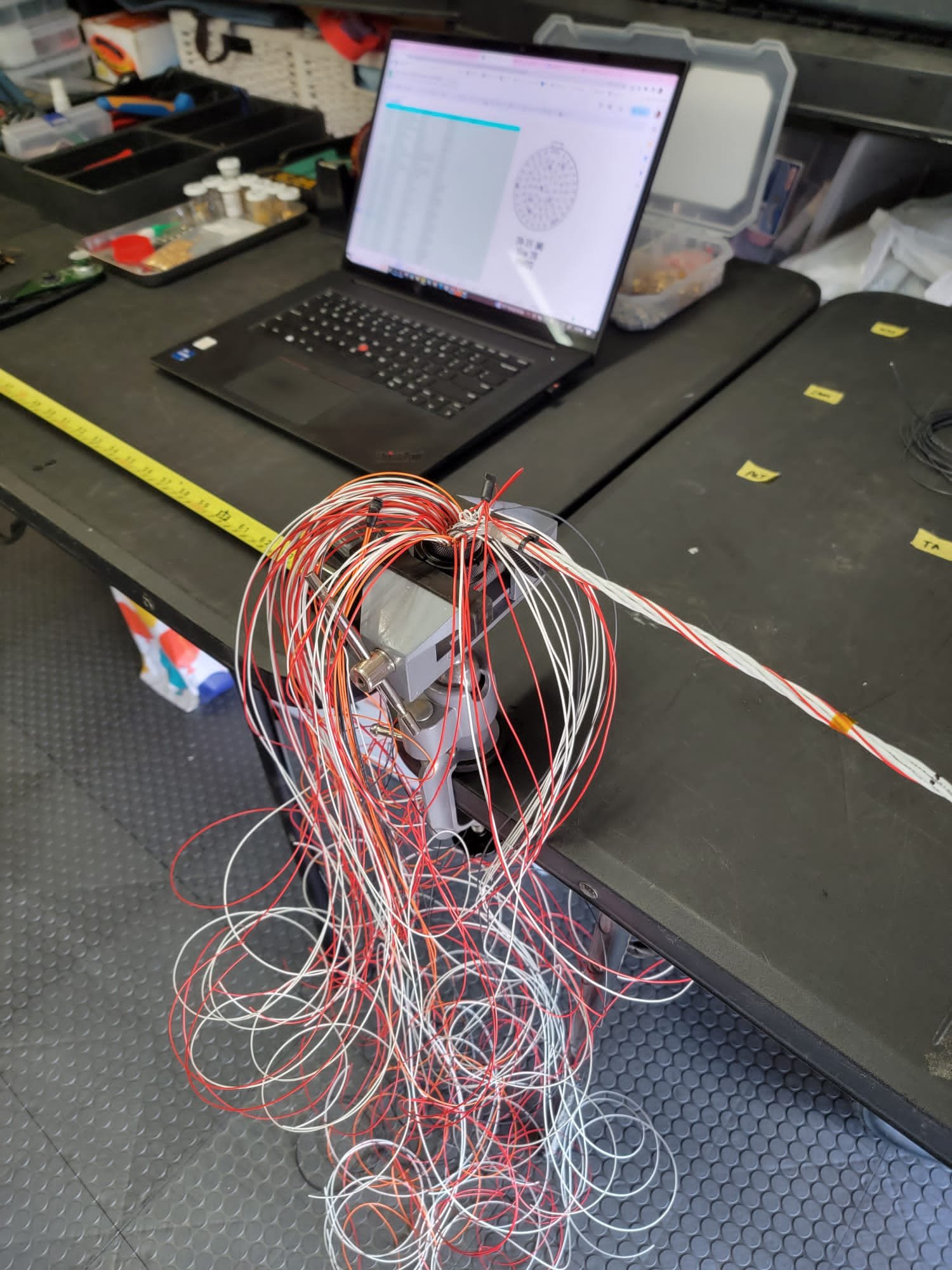

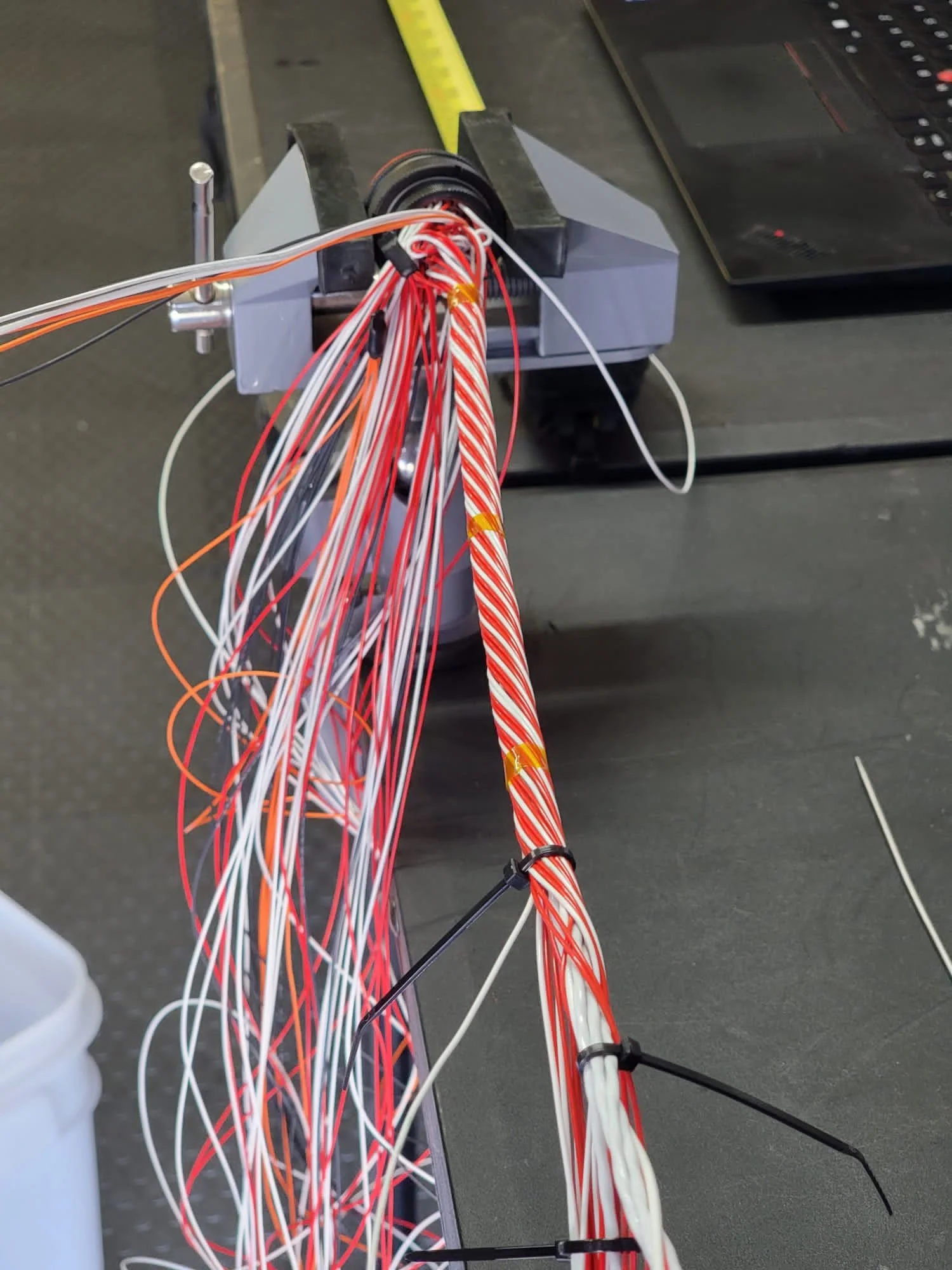

Trackspec Autosports Motorsport-grade harnesses

In order to do things right, Jon and I decided that we should re-wire the entire car to get the most out of the new KV8 ECU from EMtron and many other things that the car didn’t have before (I’ll talk more about those later). Over the course of several weeks, Jon methodically built a brand new engine harness, chassis harness, and PDM harness.

EMtron KV8 ECU

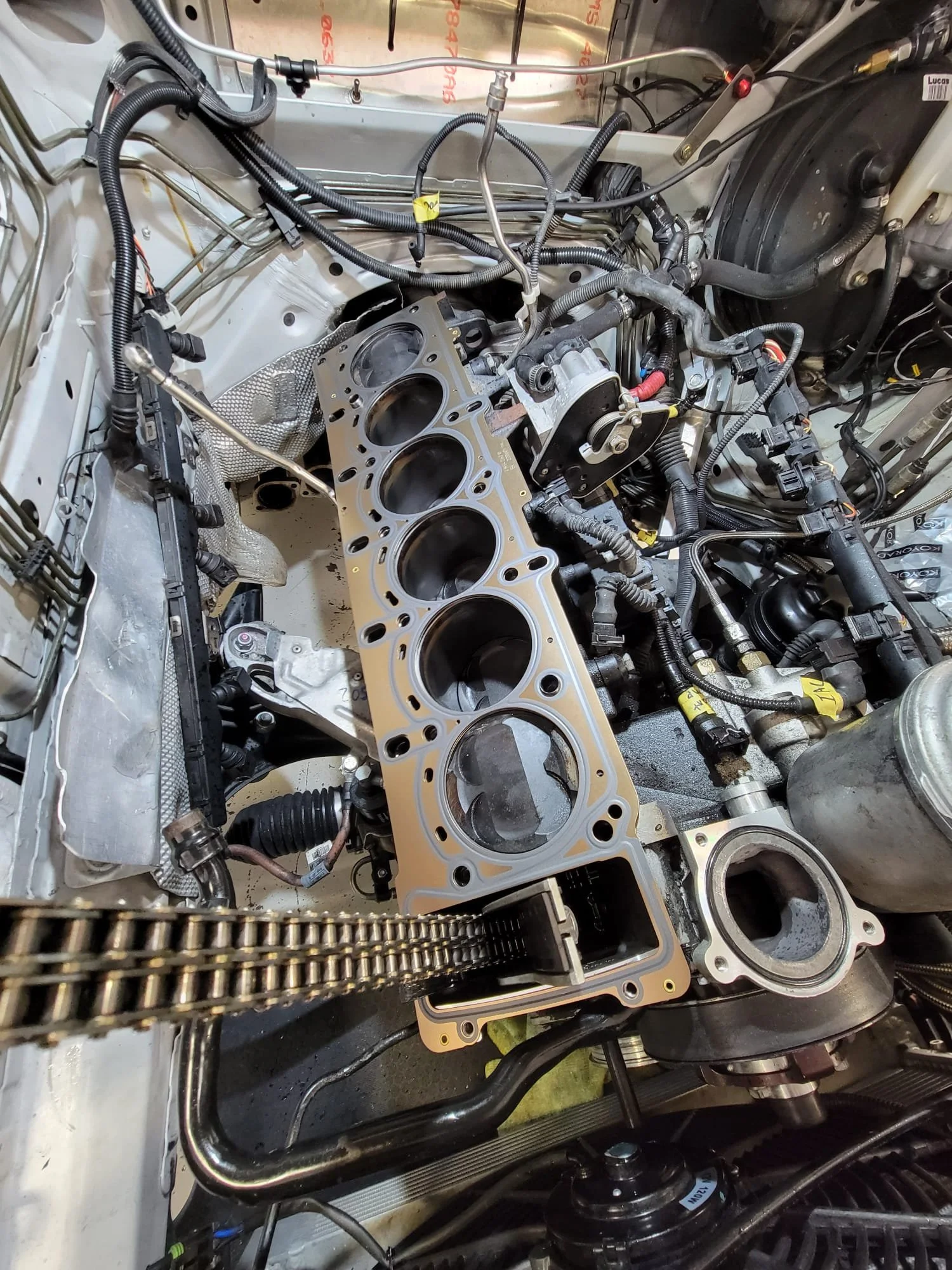

The S54 engine is very capable, but since we’re planning to more than double the original amount of horsepower that BMW intended it to have, we decided to start by doing some head work to handle the boost. Shout-out to Nate and Derek from Steeldust Machine for building us a beautiful head with bronze guides, Supertech Performance valves (oversized intake, standard exhaust), titanium springs, and retainers. It should be more than able to handle the power levels we intend to reach. But we are also working on building another engine with upgraded forged Supertech pistons later in the year. Either one might serve as a great back-up.

Built S54 Head with supertech Valvetrain

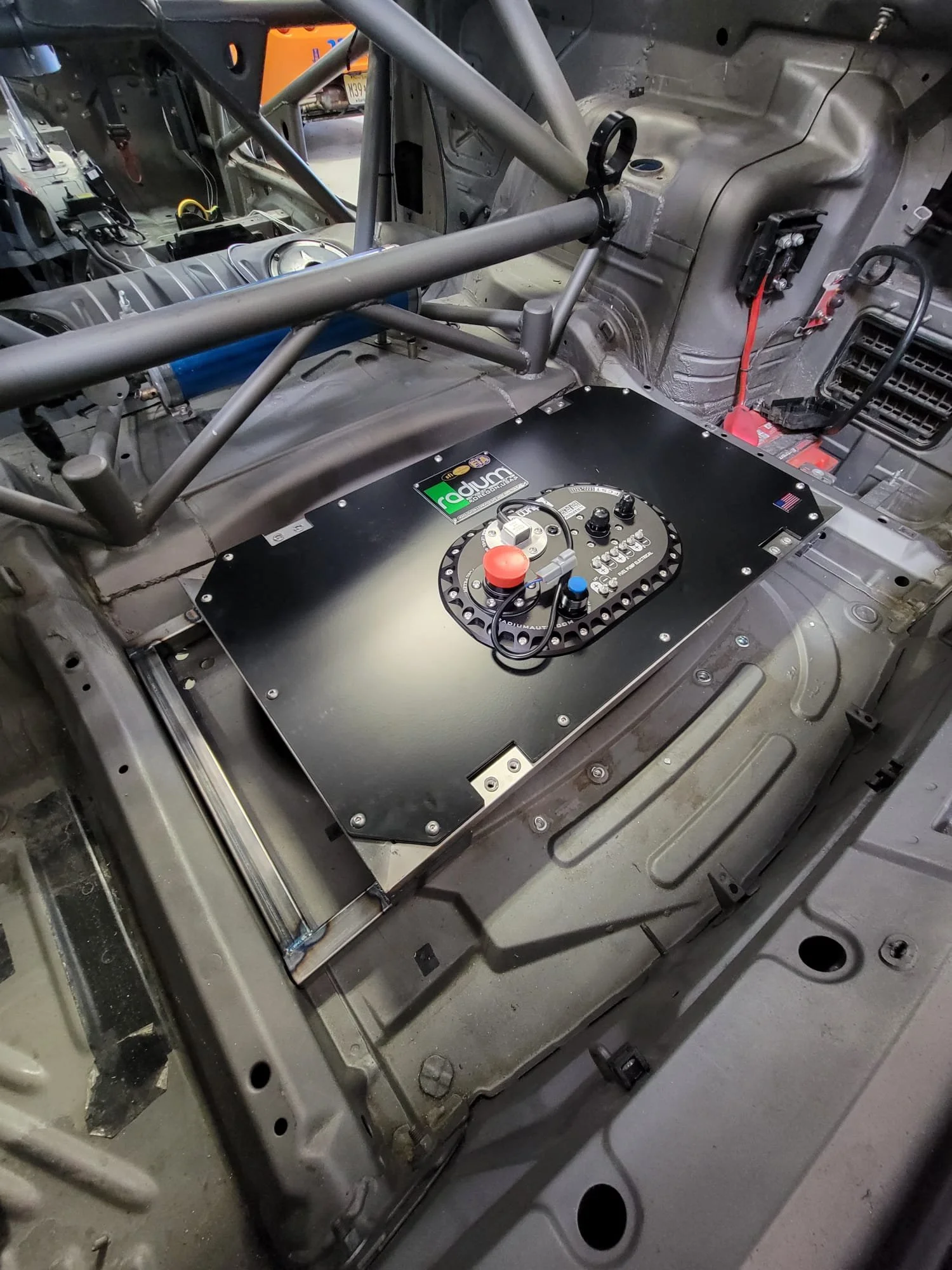

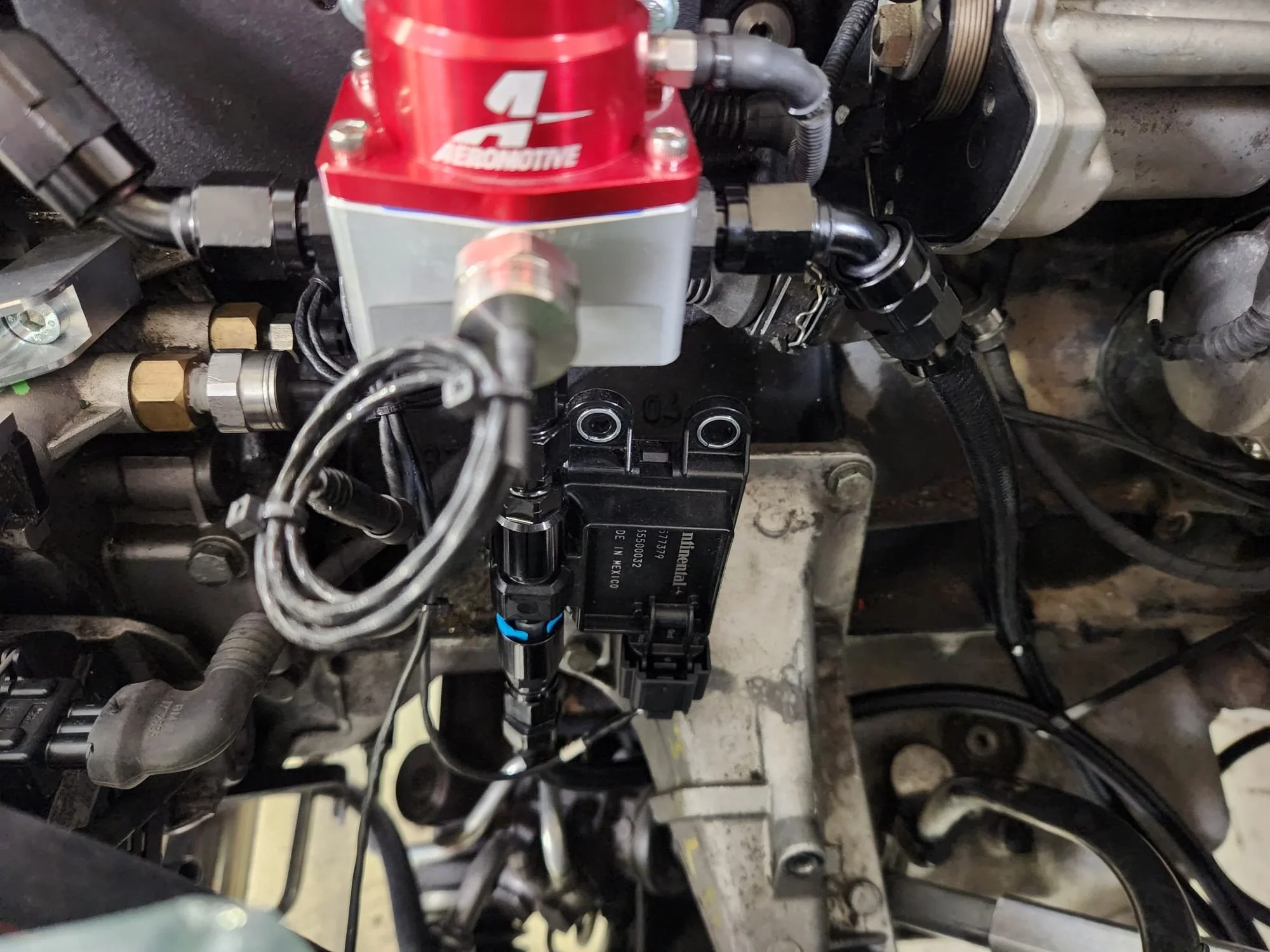

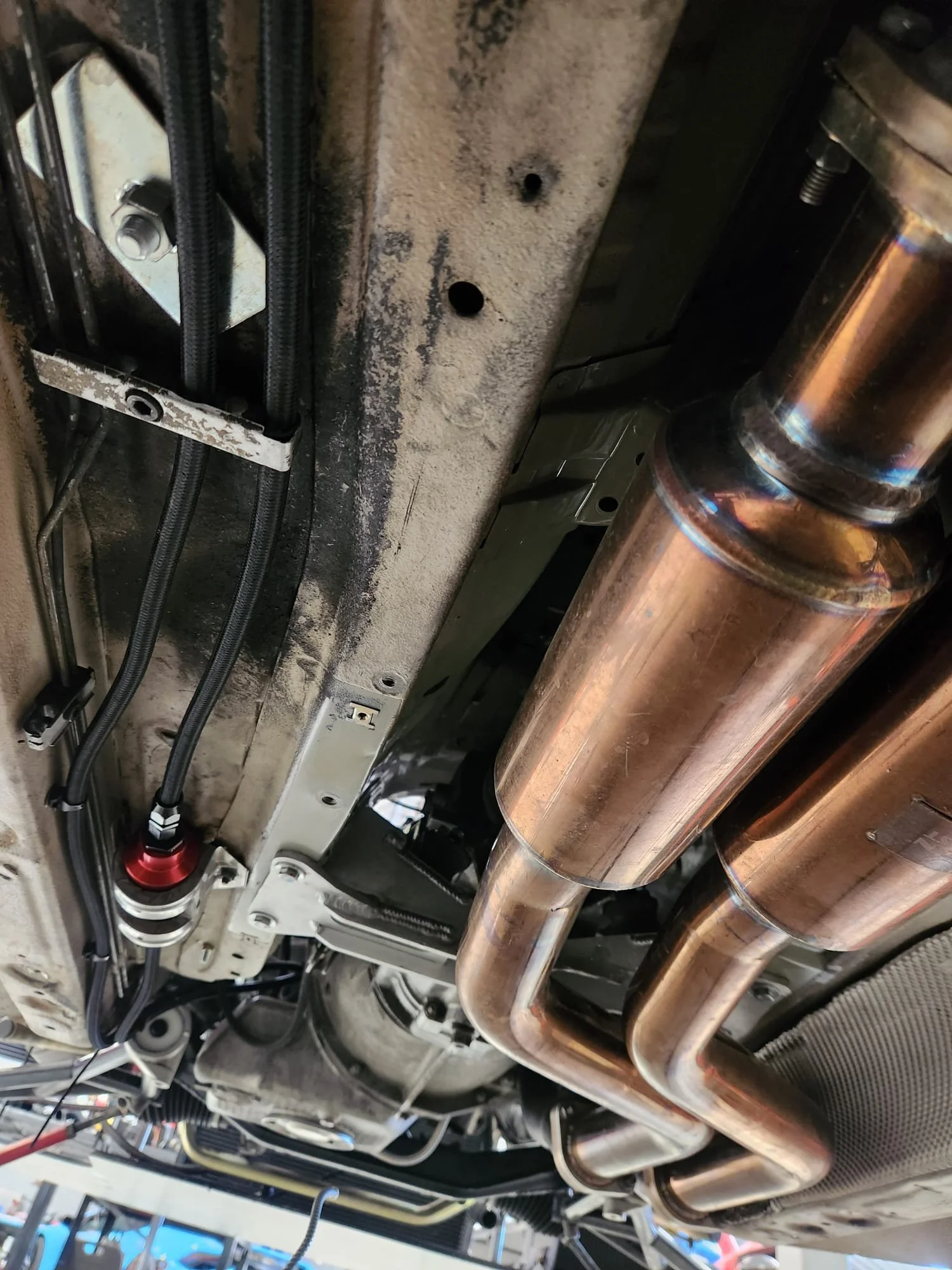

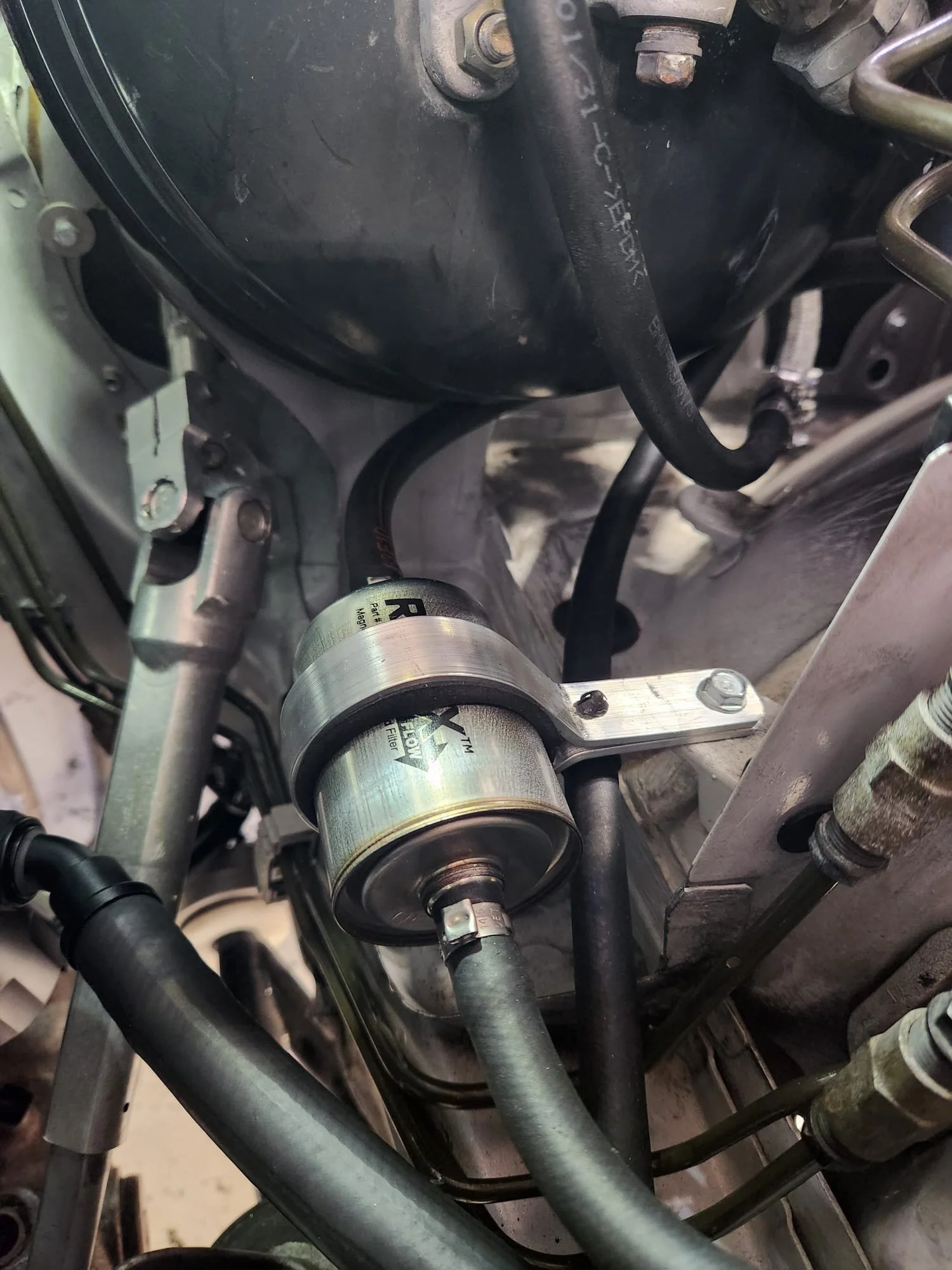

Adequate and safe fuel-delivery is going to be key at Pikes Peak. So when it came time to select a fuel-cell for our build I had only one company in-mind, Radium Engineering. A huge thank you to Aaron and the team at Radium for your many years of partnership across many different platforms. They are terrific technical partners and we are so stoked to be running Radium’s FIA-certified 14-gallon fuel cell, integrated dual surge pumps, and a whole host of other goodies (including dry break quick-fill dump cans).

Radium engineering fuel system

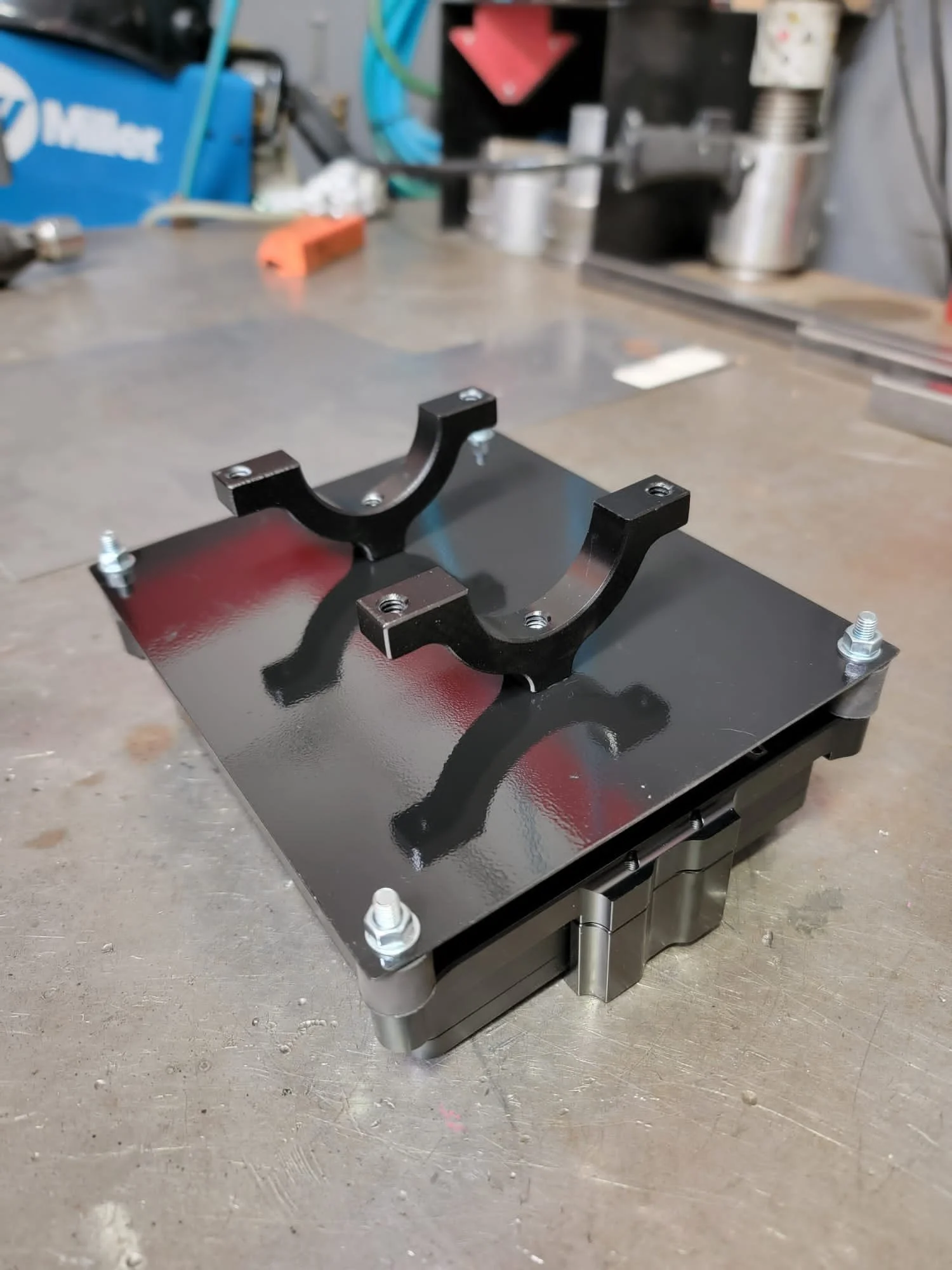

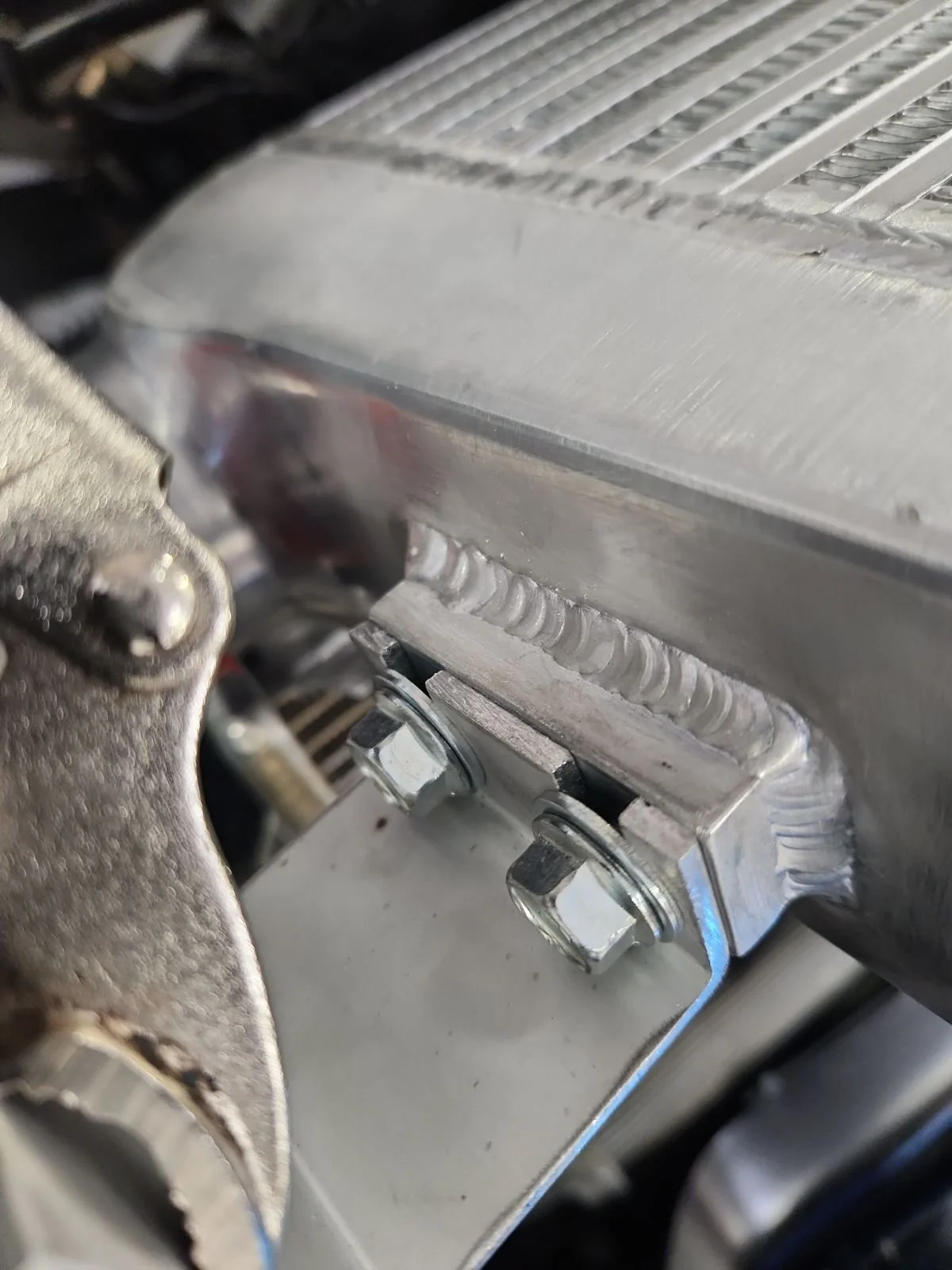

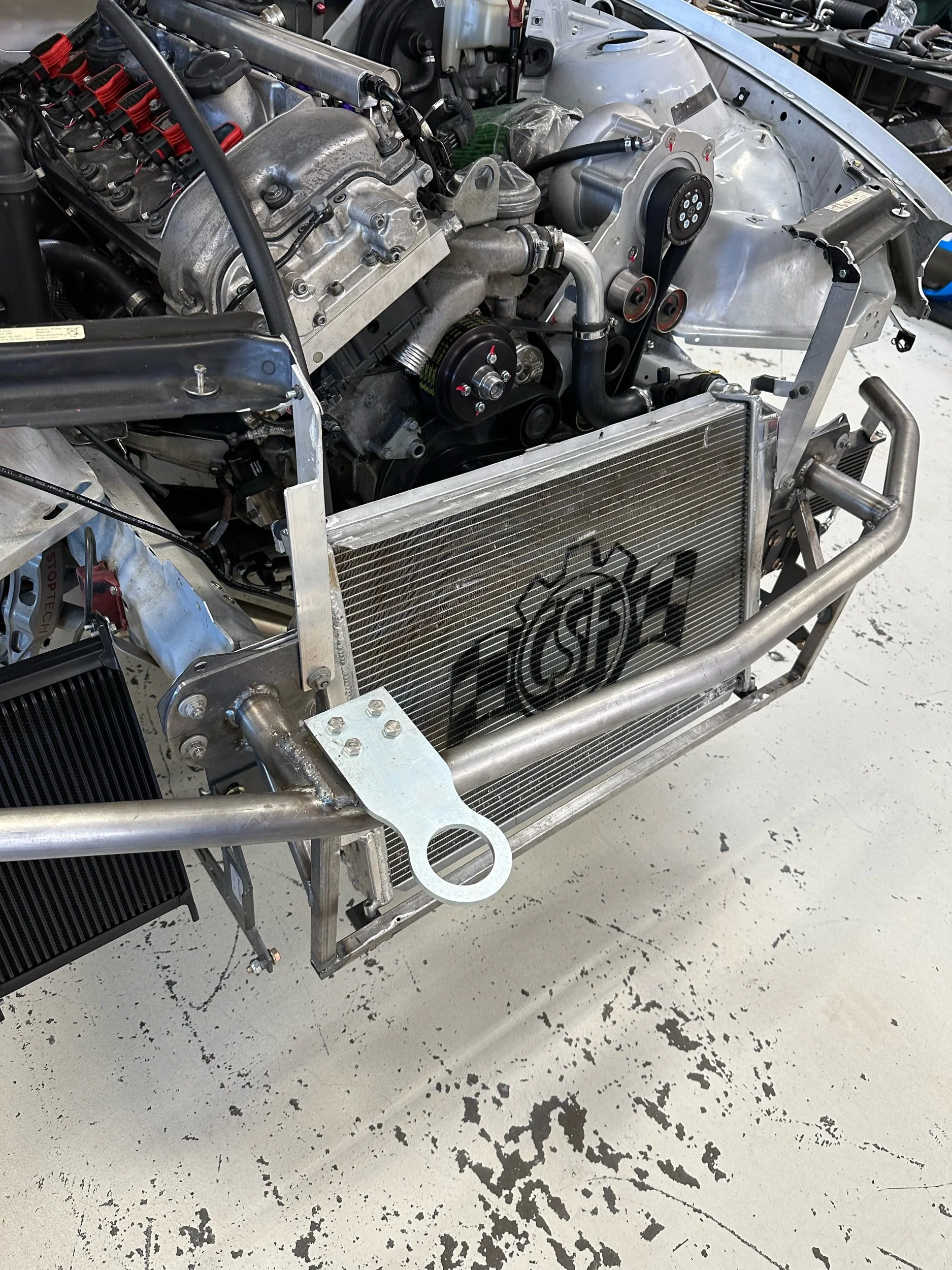

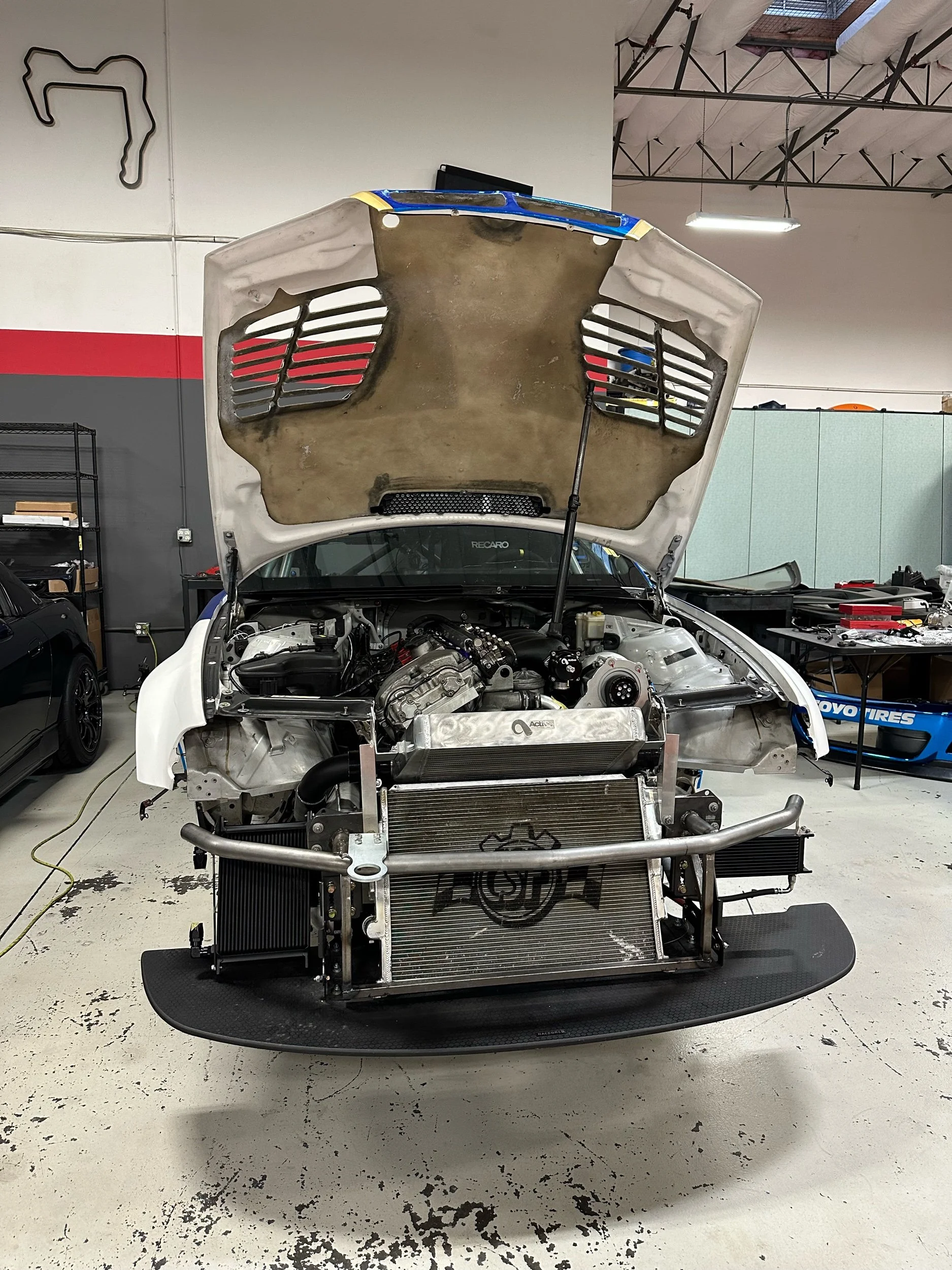

I mentioned the additional cooling demands of Pikes Peak earlier, and so from the get-go I wanted to run a v-mounted radiator and intercooler setup. The problem is, there isn’t much room in an E46 M3 engine bay because the inline-6 engine takes up a lot of space. So, we decided to take matters into our own hands and tube the front-end. This would become the foundation for mounting many other things, including oil-coolers, a new tow-hook, future much larger chassis-mounted splitter, etc.

tubular Front End

Mike and Matteo did an awesome job of fabricating the front end to accommodate the huge Active Autowerke intercooler and CSF radiator. It took some creative ingenuity (we know why a v-mount on an E46 M3 with an S54 is such a rare sight now), but we were able to make everything fit with the bumper on and hood closed. Woohoo!

V-Mounted Intercooler & Radiator

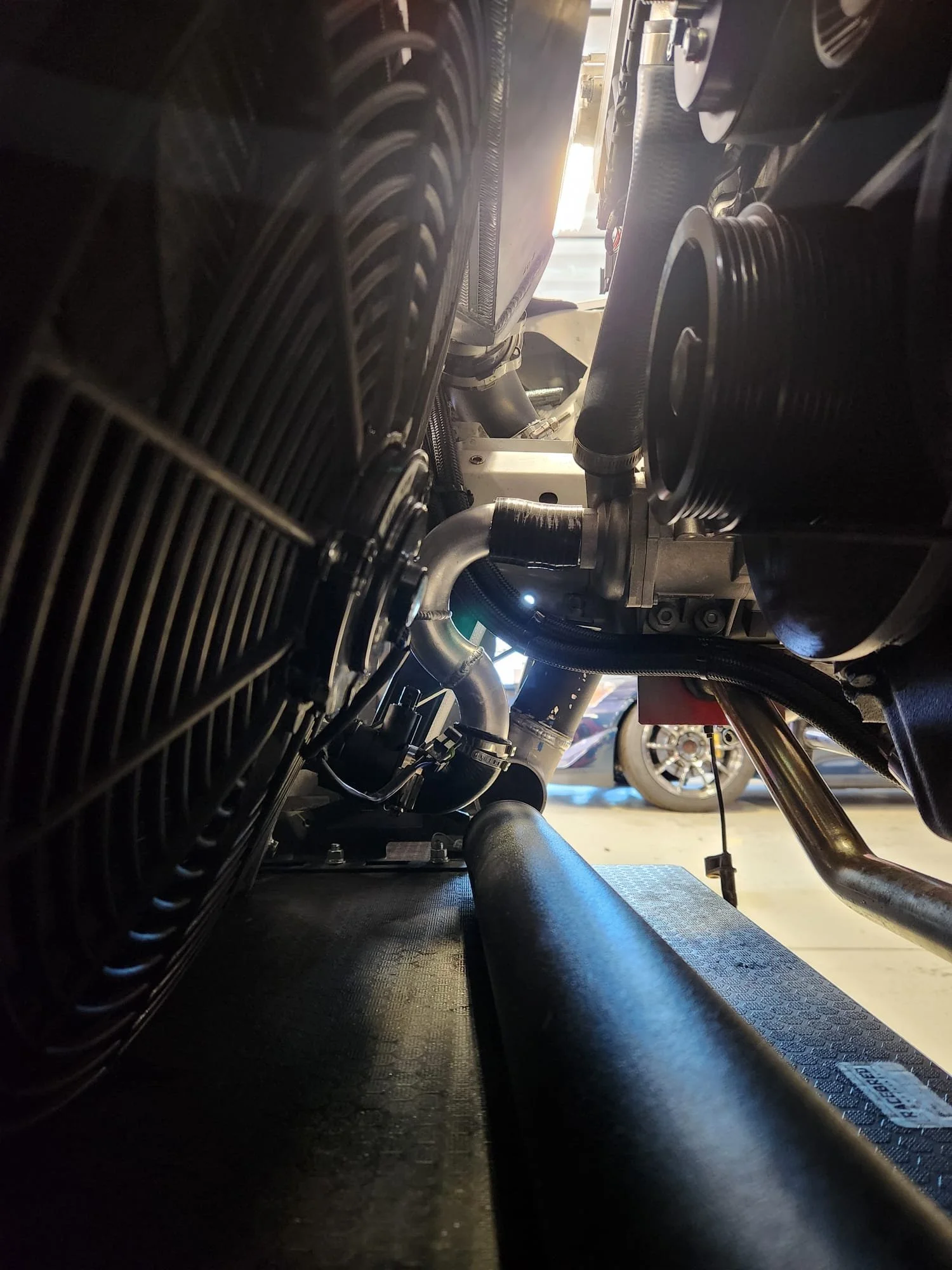

In order to achieve 600hp, we are running a C38 trim Rotrex Supercharger setup from Active Autowerke. Shout-out to Karl and team for being such helpful partners on this project. They were also the ones who recommended we ditch the factory mechanical water pump and to go with an electric water pump (EWP). Remember the cooling demands topic? Yup. It’s going to be an ongoing theme here for our Pikes Peak car.

In order to help keep our engine at the right operating temperature, we’ve opted for a Pierburg EWP from the BMW M235R race car. At full duty cycle, it pushes a whopping 30 gallons per minute. Getting this unit to fit and plumbing it correctly proved to be quite a challenge, but one that our team was definitely up for. I think it’s really cool that we are one of the few in the world to have an EWP on an S54 engine inside of an E46 M3 chassis.

Active Autowerke Rotrex Supercharger

Details Details Details

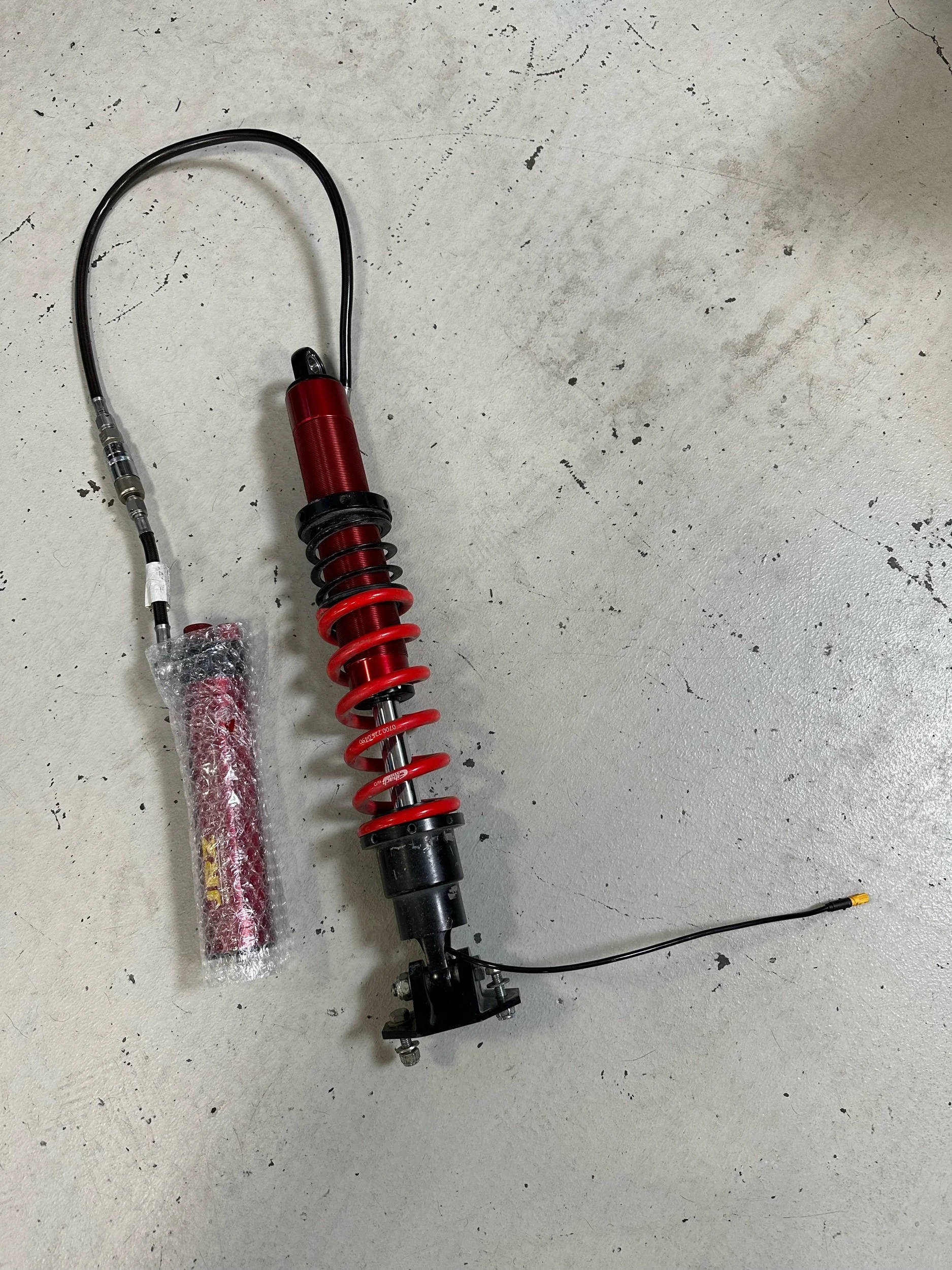

Anyone who has run Pikes Peak before knows that the mountain can be a cruel and harsh mistress. The road surface, despite being fully paved since 2011, is fast, bumpy, blind at times, and always unforgiving. So when I was talking to my longtime friend, Erik Ras at JRZ Suspension Engineering, he recommended we upgrade my 4-way motorsport dampers to JRZ’s newest technology, the PROactive damper. They are, as you might have guessed by the name, active suspension. Meaning things like damping force, pitch/dive, and roll can all be adjusted in real-time. Think Porsche PASM, but better.

I intend to do a more thorough write-up on the JRZ website later in the year, but here is the TL;DR for now. JRZ has developed a new electronically controlled valve. It is the fastest, most accurate valve on the market today. For example, Bilstein (which is who supplies Porsche with the PASM damper) operates at max 20 Hz. The JRZ PROactive runs with 300 Hz with no hysteresis and no remnant magnetism during operation.

JRZ PROactive Unboxing

But JRZ has gone several steps further, beyond just a faster electronically controlled valve. They’ve also built a computer to control it with a proprietary algorithm. While most active dampers look at controlling sprung mass (vehicle body where the passenger sits), the un-sprung mass (wheels, tires, brake calipers, lower control arm) is the mass that actually has the contact with the road; it is equally important.

JRZ’s algorithm calculates the natural frequencies of both the sprung mass and un-sprung mass and it controls both. This ensures the most possible contact patch of the tire to the ground; resulting in ultimate grip at all times and also maximum comfort (which translates into better drivability). Yeah…wow.

JRZ PROactive Assembly

The first time we fired up our newly supercharged Pikes Peak Hill Climb car was really memorable. Everyone, Jon, Mike, Isaac, Matteo, and I were really excited to hear this beast roar to life after months of hard work.

First Fire Up

Shortly after we got the car started, we drove her onto the alignment rack for some initial setup. Notice the new JRZ PROactive computer controller inside the cabin, and the Radium fuel-cell sticking out from under the rear bumper.

Alignment & Corner Balancing

We brought the car over to Jei at Blacktrax to begin building the ignition and fueling tables, and to look at how we want to control the EWP. We had a great first session, and look forward to being back soon.

First Dyno Session at Blacktrax Performance

Check Back Soon for part 2!

Tuning for big power on the dyno with Jei

First shakedown